Ceramic flat film

(1) Product positioning

Membrane separation technology has been internationally recognized as one of the most promising high-tech applications in the 21st century, known as the Fourth Industrial Revolution, and ceramic membranes are among the best in membrane technology.

The research on ceramic membranes began in the 1940s, and after successful promotion and application in the dairy and beverage industries in France in the early 1980s, the separation technology and industrial status of ceramic membranes were gradually established.

The research on ceramic membranes in China began in the early 1980s and entered the 1990s. The former National Science and Technology Commission organized scientific and technological breakthroughs in the industrialization technology of inorganic ceramic membranes, promoting the industrialization process of ceramic microfiltration membranes. The national "863" plan also includes the "Inorganic Separation Catalytic Membrane" project.

Ceramic membranes are mainly divided into three types: flat, tubular, and multi-channel. Among them, ceramic flat membranes rank first among ceramic membranes due to their advantages such as large filtration area, good chemical stability, acid and alkali resistance, high temperature resistance, strong microbial resistance, high separation accuracy, high mechanical strength, easy regeneration, and long service life.

(2) Product characteristics

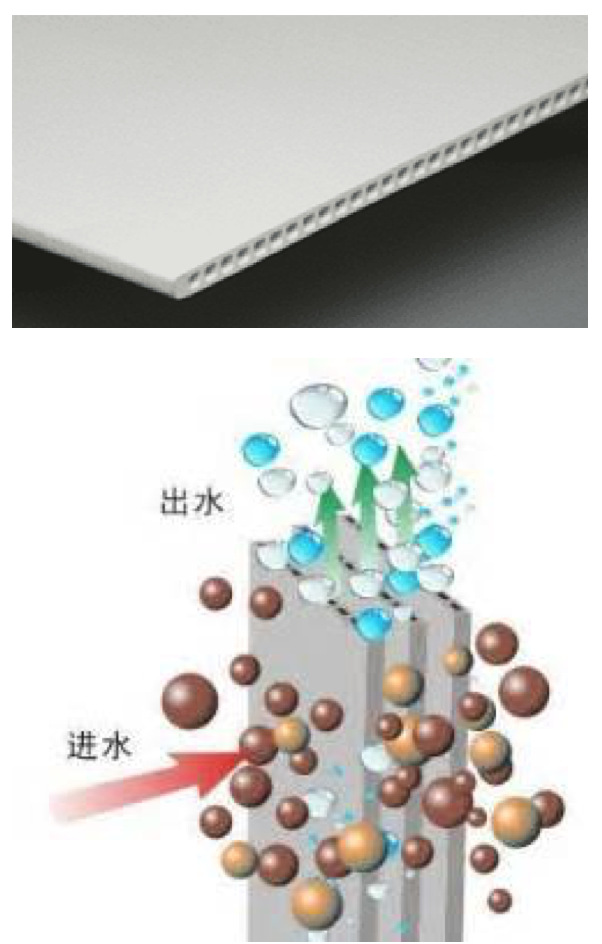

Ceramic flat membrane is a new generation of ceramic membrane technology, which is a porous separation material made from Al2O3, ZrO2, TiO2, SiO2, SiC and other raw materials through a series of special processes.

The pore size of ceramic flat membrane covers the range of ultrafiltration, microfiltration, and nanofiltration. Its filtration pore size can be adjusted from 10 nanometers to 10 micrometers depending on the filterable medium, with a narrow pore size distribution. The membrane surface can be modified with different materials to increase filtration accuracy and flux.

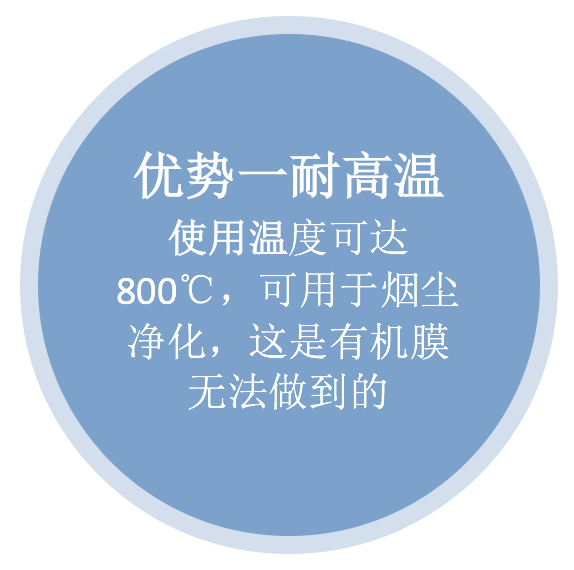

The principle of ceramic flat membrane separation: Driven by the pressure difference on both sides of the membrane, when the feed liquid flows through the membrane surface, only water, inorganic salts, and small molecule substances are allowed to pass through the membrane, while preventing the passage of suspended solids, glue, and microorganisms and other large molecule substances in the water.

(3) Product advantages

1. High temperature resistance: Ceramic flat membrane is made of inorganic materials such as aluminum oxide with a special structure, and is fired through a special production process. The firing temperature is above 1000 ℃, so the use temperature of ceramic flat membrane can be higher than 400 ℃, or even up to 800 ℃. Therefore, it is particularly suitable for direct separation of high-temperature products. In addition, it can be directly cleaned and sterilized by high-temperature steam when used in the fields of food and biotechnology.

2. Good stability: Ceramic flat film can withstand acid, alkali, and organic solvents, and is suitable for a wide pH range. Therefore, it can be used in highly corrosive media and can be cleaned with chemical reagents.

3. High mechanical strength: The separation membrane of ceramic flat membrane is prepared in the form of a support body as the carrier, and its mechanical strength is much higher than that of organic membrane. Therefore, it can be used under high pressure, and the membrane components and micropores will not deform or be damaged; High pressure recoil can also be used for regeneration.

4. Long service life: With good resistance to microbial erosion and biochemical compatibility, it is easy to achieve membrane regeneration. Inorganic membrane components have a service life of over 10 years, which is 3-5 times that of organic polymer membranes.

5. High separation efficiency: The pore size distribution of ceramic flat membrane is narrow, and the asymmetric membrane structure can significantly improve the removal rate of characteristic pollutants and specific molecular weight solutes. The ceramic flat membrane has a large flux and adopts an immersion installation method, resulting in a water output of up to 5 times that of traditional membranes.

6. Low energy consumption: According to the "physical screening" theory, within a certain range of membrane pore size, depending on the diameter of the filtering material, only water, inorganic salts, and small molecule substances are allowed to pass through the membrane, while preventing the passage of large molecules such as suspended solids, glue, and microorganisms. Therefore, material separation can be achieved with very low pressure.