By using pre-treatment, reverse osmosis technology, ultra purification treatment, and post treatment methods, the conductive medium in the water is almost completely removed, and the non dissociative colloidal substances, gases, and organic substances in the water are also removed to a very low level, resulting in a water resistivity greater than 10 megaohms and even up to 18.25 megaohms.

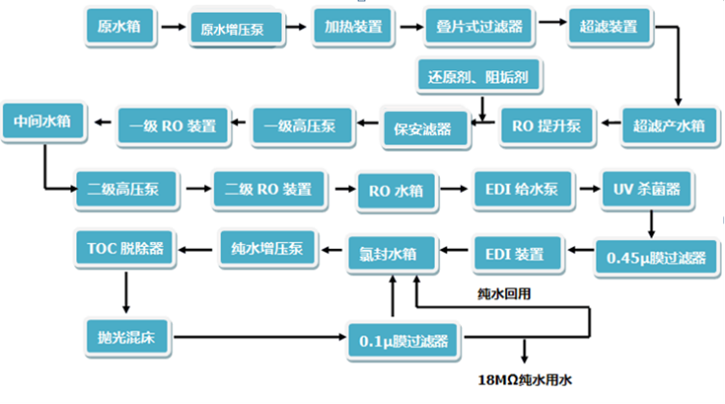

The ultra pure water treatment system consists of four units: pre-treatment, reverse osmosis, ultra purification, and terminal ultrafiltration. Tap water first passes through a pre-treatment unit to remove larger particles, suspended solids, and some organic matter from the water. Then enter the reverse osmosis unit to intercept and remove ionic substances and macromolecular substances (such as viruses, microorganisms, etc.) from the water. Afterwards, the remaining minor ions after membrane removal are purified and ultrapurified through purification and ultrapurification units, reducing the ion content in the water to trace levels. Finally, UV, ultrafiltration and other technologies are used to ensure that the microorganisms, organic matter, and pyrogens in ultrapure water meet various experimental application requirements.

Ion exchange in ultrapure water systems is a special solid adsorption process that occurs in an electrolyte solution of ion exchange agents. A typical ion exchange agent is a solid granular substance that is insoluble in water, known as an ion exchange resin. It can absorb a certain cation or anion from the electrolyte solution, and exchange another ion with the same charge symbol it contains equally, and release it into the solution, which is called ion exchange. According to the type of ion exchanged, ion exchangers can be divided into two categories: cation exchangers and anion exchangers.